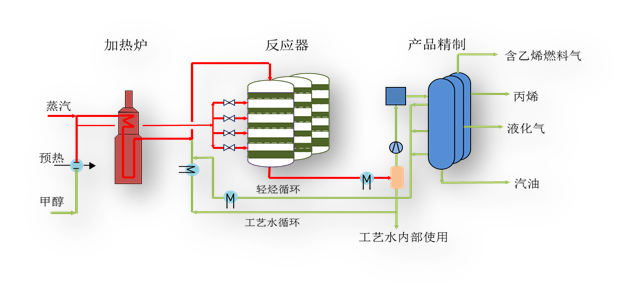

Technology brief

Under suitable process conditions and special catalyst, methanol is dehydrated and cracked to produce low-carbon olefins, mainly ethylene and propylene. Meanwhile, a small amount of carbon four components rich in isobutylene and blending components of high octane gasoline are produced. This technology is a new technology combining coal chemical industry with petrochemical industry. It effectively integrates methanol to propylene, light hydrocarbon aromatization, etherification and other process technologies, so as to maximize the production of propylene from methanol or propylene and high octane gasoline blending components.

Technical characteristics

Adopting the methanol cracking technology developed by Luoyang Kechuang Petrochemical Co., Ltd., the production scheme can be flexibly adjusted according to the market situation, which can produce propylene to the maximum extent and produce propylene as well as high octane gasoline blending components.

MTP: yield of diene (propylene + ethylene) ≥ 28%; mtpg: yield of diene (propylene + ethylene) ≥ 22%, yield of gasoline ≥ 15%, Ron ≥ 95.

Technological superiority

① the process technology adopts our company's proprietary kcp-ml series catalyst, which has obvious advantages compared with similar foreign technologies:

A. after special modification, the zeolite catalyst has strong anti coking ability, single operation cycle > 30 days, and total catalyst life ≥ 1.0 years.

B. catalyst activity, hydrothermal stability and propylene selectivity are good.

② the technology is advanced, mature and reliable, and it is the first to realize industrialization in China. At present, many sets of industrial devices have been put into use.

③ the processing energy consumption of the device is low, 30-40% lower than that of similar technologies.

④ high level on-site technical service and training.

Industrial application

The technology has been applied in a number of 300-400000 T / a methanol to olefin industrial units.