Technology brief

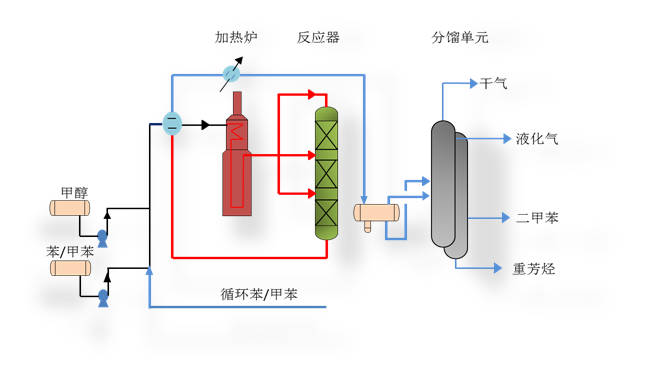

The alkylation technology of benzene / toluene with methanol, using modified zeolite as catalyst, using its shape selective catalytic function, can produce target aromatics with high selectivity. It is a new technology for producing mixed aromatics or gasoline blending components with high octane number. The process technology and proprietary catalyst independently developed by Luoyang Kechuang Petrochemical Co., Ltd. can convert benzene / toluene and methanol into xylene products rich in p-xylene according to market demand, providing raw materials for xylene separation unit.

Technical characteristics

① good catalyst performance

The zeolite with high activity and stability was used as the active component of the catalyst, and it was specially modified to make its pore structure suitable and improve the selectivity of the target product.

② when the raw material is benzene, the selectivity of toluene and xylene can be flexibly adjusted. The selectivity of the target product toluene and xylene can be easily adjusted by adjusting the operating conditions, so as to adapt to the market changes and increase the enterprise benefits.

Technical index

The technology has the characteristics of high conversion rate of raw materials and good selectivity of target products. One way conversion of benzene and toluene is more than 30%, methanol conversion is more than 99.7%, and methanol methylation rate is more than 85%.

Industrial application

The technology has been applied in a 200000 t / a benzene methylation plant of a petrochemical enterprise in Xinjiang.